Snapmaker Artisan Update #3 | Artisan’s Pilot Prototype in Action

Hi makers,

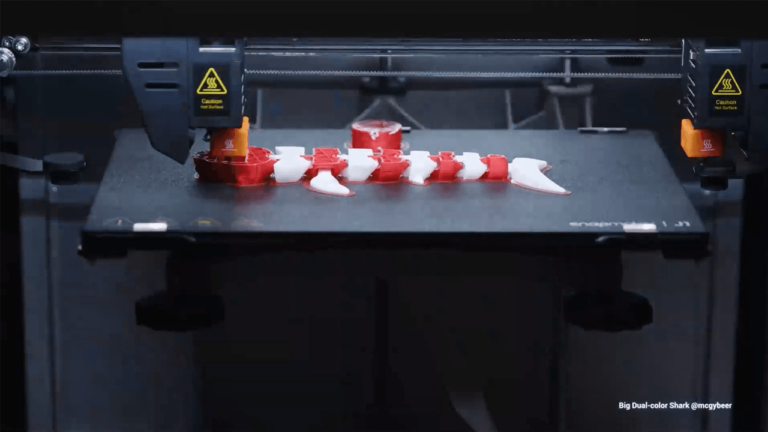

Many of you are asking to see Artisan in action, so we did a project for each function. Hope you enjoy the videos below!

Hi makers,

Many of you are asking to see Artisan in action, so we did a project for each function. Hope you enjoy the videos below!

“I searched the Internet and came across the Snapmaker and my blood pressure rose enormously. Yes!!! This is the part I must have.”

This year, 2024, Snapmaker headed out to Frankfurt to take part in Formnext, one of the world’s largest 3D Printing and Additive Manufacturing Expos! We partnered with our premiere Northern European Distributor, 3D Prima, to make our presence known, meet with Snapmaker fans, and catch the latest scoops from the world of 3D Printing. Setup…

3D printing can make your business soar in a matter of months. It makes the manufacturing process more efficient and is great for prototyping products that will help you reach the market faster. Whether it’s fashion, furniture, architecture models, automotive spare parts, medical implants, or just to channel your creativity, 3D printed models are the…

Our focus remains on developing cutting-edge products, expanding market presence, fostering partnerships, and elevating Chinese brands worldwide.

We are here to assure you that we’ll keep you posted with the manufacturing progress and shipment of each batch of Artisan during this whole time.

This is really cool, will the laser module also be equipped with a air assist too? There are some videos on the internet how people build it themselves with high air pressure. Seems that the results can be much better with high pressure air. Now rolling out this superior product, I think this is a missing feature

Hi Steffen, thank you very much for your suggestion. The 10W Laser Module is not equipped with an air assist. However, the unique wind channel inside the 10W Laser Module provides excellent wind pressure, blowing the fumes away as the laser beam cuts into the material, sending the fumes directly into the grids of the Laser Engraving and Cutting Platform, which then get channeled out, reducing their interference on laser machining.